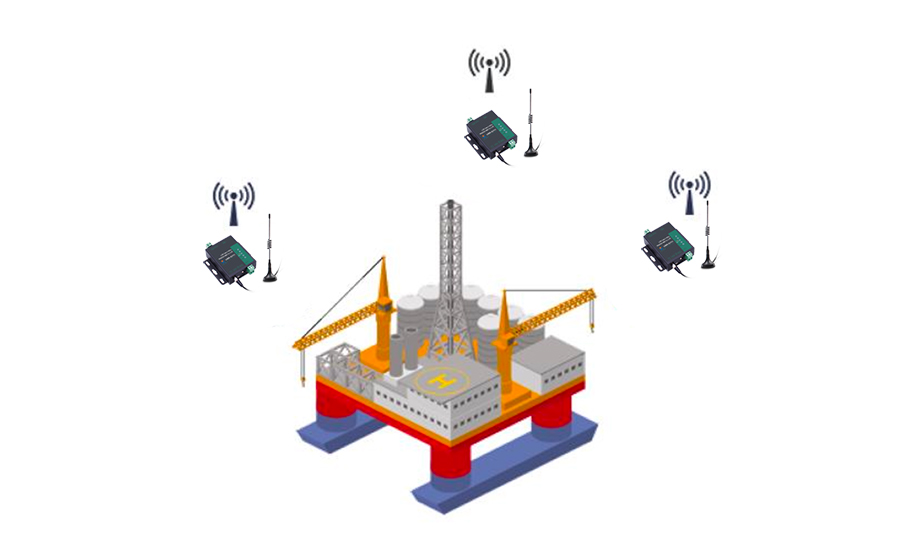

Industrial Modem plays a crucial role in the remote monitoring and networking applications in the petroleum and petrochemical industry. It can efficiently transmit real-time data collected by petroleum and petrochemical facilities distributed in a vast area, such as pressure, temperature, flow and other key parameters, to the central monitoring center through stable wireless network. This networking application not only ensures the real-time and accuracy of data, but also greatly improves the efficiency and reliability of remote monitoring, providing strong technical support for the safe production and efficient operation of the petroleum and petrochemical industry.

The petroleum and petrochemical industry involves multiple links such as exploration, drilling, logging, and refining, which often require field work. The distance between the operation site and the company is long, making information exchange difficult. The traditional manual inspection method is not only inefficient, but also has potential safety hazards. Therefore, it is particularly important to develop an efficient and reliable remote monitoring system.

In the remote monitoring system of the petroleum and petrochemical industry, Industrial Modem plays a central role. The entire system mainly consists of the following parts:

Information collection substation: located at various operation sites, responsible for collecting key data such as temperature, pressure, and flow. These data are converted into analog signals by sensors and then converted into digital signals by A/D converters.

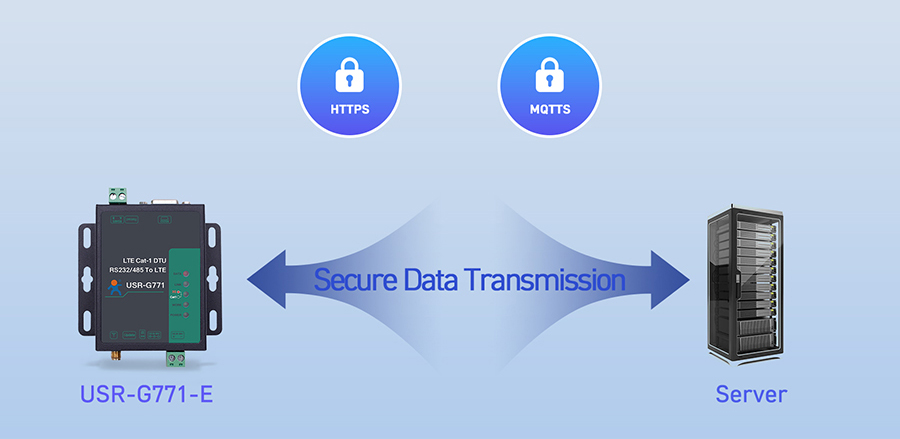

Industrial Modem: Transmit the collected digital signals to the monitoring center through wireless networks such as GPRS. The IoT Modem has the characteristics of low power consumption and high performance, and can transmit data stably and reliably.

Monitoring center: receive and process data from various information collection substations, conduct real-time analysis, trend prediction, and abnormal alarm. The monitoring center is usually equipped with high-performance computers and professional monitoring software.

The following is a specific practical case that demonstrates the application of Industrial Modem in remote monitoring in the petroleum and petrochemical industry:

Case 1: Remote monitoring system for oil extraction field in oil field

The oil field production site consists of multiple oil wells, metering rooms, manifold valve groups, and other facilities. The working status of these facilities and the data of the produced oil products directly affect the stability of oilfield production and the quality of crude oil. Traditional inspection methods have many shortcomings, so a remote monitoring system based on IoT Modems has been developed.

Install information collection sub-stations at each oil well site, including sensors, A/D converters, and IoT Modemss. The sensor is responsible for collecting data such as temperature and pressure of the oil well, and the A/D converter converts these data into digital signals, which are then transmitted to the monitoring center through the IoT Modems.

The monitoring center receives and processes these data, and displays them to the staff through a graphical interface. The staff can view the working status of each oil well in real time and take timely measures when anomalies are detected.

The system greatly improves the production efficiency of the oilfield and reduces the labor intensity of workers. At the same time, due to the guarantee of real-time and accurate data, the production safety of the oilfield has also been significantly improved.

Case 2: Remote monitoring system for natural gas extraction site

Natural gas extraction sites are often located in remote areas with harsh environments, and traditional inspection methods face many difficulties. Therefore, a remote monitoring system based on IoT Modems has been developed to monitor the operational compliance of workers and the working status of equipment.

Install high-definition cameras and IoT Modemss at the natural gas extraction site. The cameras capture the operation images of workers, and the IoT Modemss transmit these images to the monitoring center. At the same time, sensors are installed on key equipment to monitor the working status of the equipment.

The staff in the monitoring center can view the live images and equipment data in real time, and intervene in time by remote shouting or sending instructions when illegal operations or equipment anomalies are detected.

The system effectively avoids safety accidents caused by illegal operations and equipment malfunctions, and improves the efficiency and safety of natural gas extraction.

The application of Industrial Modem in remote monitoring in the petroleum and petrochemical industry has significant advantages. It can transmit data stably and reliably, enabling remote monitoring and real-time analysis. At the same time, due to its low power consumption and high performance, IoT Modems can adapt to various harsh environments. By introducing IoT Modems technology, the petroleum and petrochemical industry can greatly improve production efficiency, reduce operating costs, and ensure production safety.